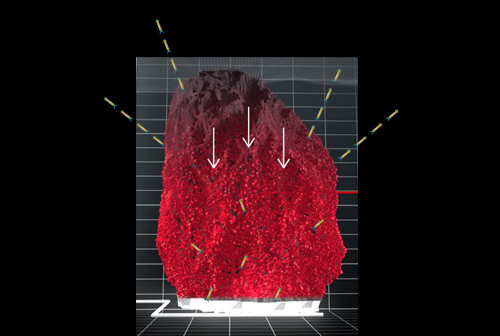

Networked Smart Markers allow miners to measure where your cave back is, without worrying about cables shearing at the wrong place. This allows miners to manage their caving risks by knowing what’s actually happening within the mine.

During the phase of growing the cave to breakthrough, understanding the cave back location is critical for making informed decisions. Current methods for monitoring and managing cave back are unable to provide all of the data required by mine operators.

Elexon Mining has developed the Networked Smart Marker System to complement existing monitoring systems. This system enhances knowledge of cave back behaviour, offering insight into areas not previously visible to mine operators. With this enhanced knowledge, mine safety and economic risks can be more effectively managed.

How the Networked Smart Marker System works:

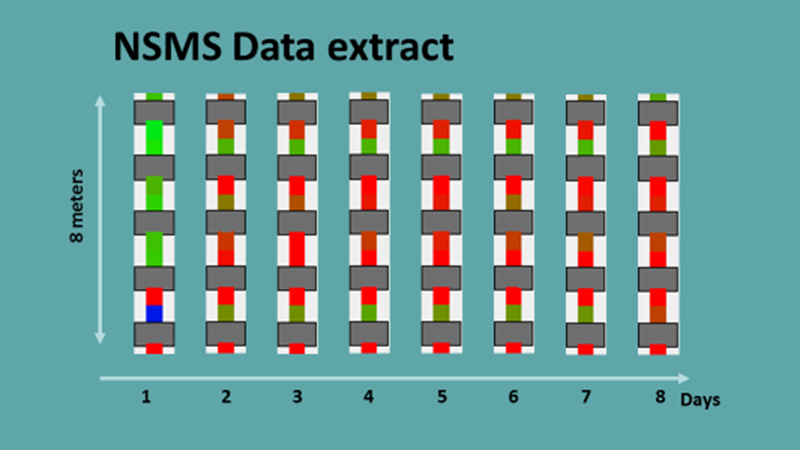

Arrays of Networked Smart Markers are installed and grouted in holes. The Markers communicate with neighbouring Markers which enables them to share data wirelessly through rock over long distances. Markers record radio signal strength for communication between Markers.

Radio signal strength is directly related to the distance between Markers. Changes in radio signal strength over time indicates movement between Markers until the Markers move too far apart, which is when communication is interrupted.

Networked Smart Markers can monitor holes hundred’s of metres long. This communication does not rely on cables which means that ground movement in the range of a few metres does not break communications, unlike cable based monitoring systems.

This recorded data is analysed to identify the cave back’s location and cave growth. Ground movement of up to several metres will not break the communication chain of Markers.

Networked Smart Markers are based on Elexon Mining’s rugged, blast proof and multi-year battery-powered Smart Markers which have been successfully used in the majority of large scale cave mines for monitoring cave flow.

Contact our team to learn more about current Networked Smart Marker System installations and their outcomes, and to discuss how we can work with you to enhance your cave monitoring capabilities.

The downsides of traditional cave back monitoring solutions

Traditional cave back monitoring solutions may not provide sufficient insights into cave back monitoring and expose cave operations to the above listed risks.

- TDRs and Extensometers rely on cables for measurements, powering sensors and transmitting data back to data loggers. Due to the nature of caving, mining induces stresses in rock above and around the cave. These stresses may cause structures to open and ground to move which can happen at a far distance from the actual cave back location. This ground movement is likely to damage any cables installed in the ground. Damaged cables will render the monitoring systems inoperable or provide inaccurate readings.

- Open holes are used for lowering cameras down the hole and into the cave. Displacement of holes may obstruct the camera’s path and disable monitoring the cave back.

- Micro-Seismicity: The location accuracy of seismic events around propagation cave backs is often hampered by the changing rock mass condition that attenuate the micro seismic signals, making it difficult to evaluate the cave back’s location.