Reconciliation of the recovered resource is an important instrument for assessing the performance of sublevel caving mines. While the quality of reconciliation has improved significantly the method requires a significant period of production history in excess of 18 months before valid local conditions can be incorporated in recovery estimates. The introduction of computer models which allow processing of large datasets has greatly aided the process however the inability to measure post mining voids allows the effect of essential assumptions, made for recovery estimation, to have potentially significant impact.

Without other physical measure systems there is no possibility to either access production method improvements believed to benefit the operation or confirm that the recovery estimation process employed models the physical actuality sufficiently and with good confidence in the modelled result.

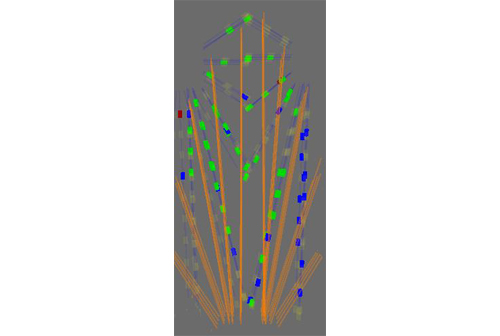

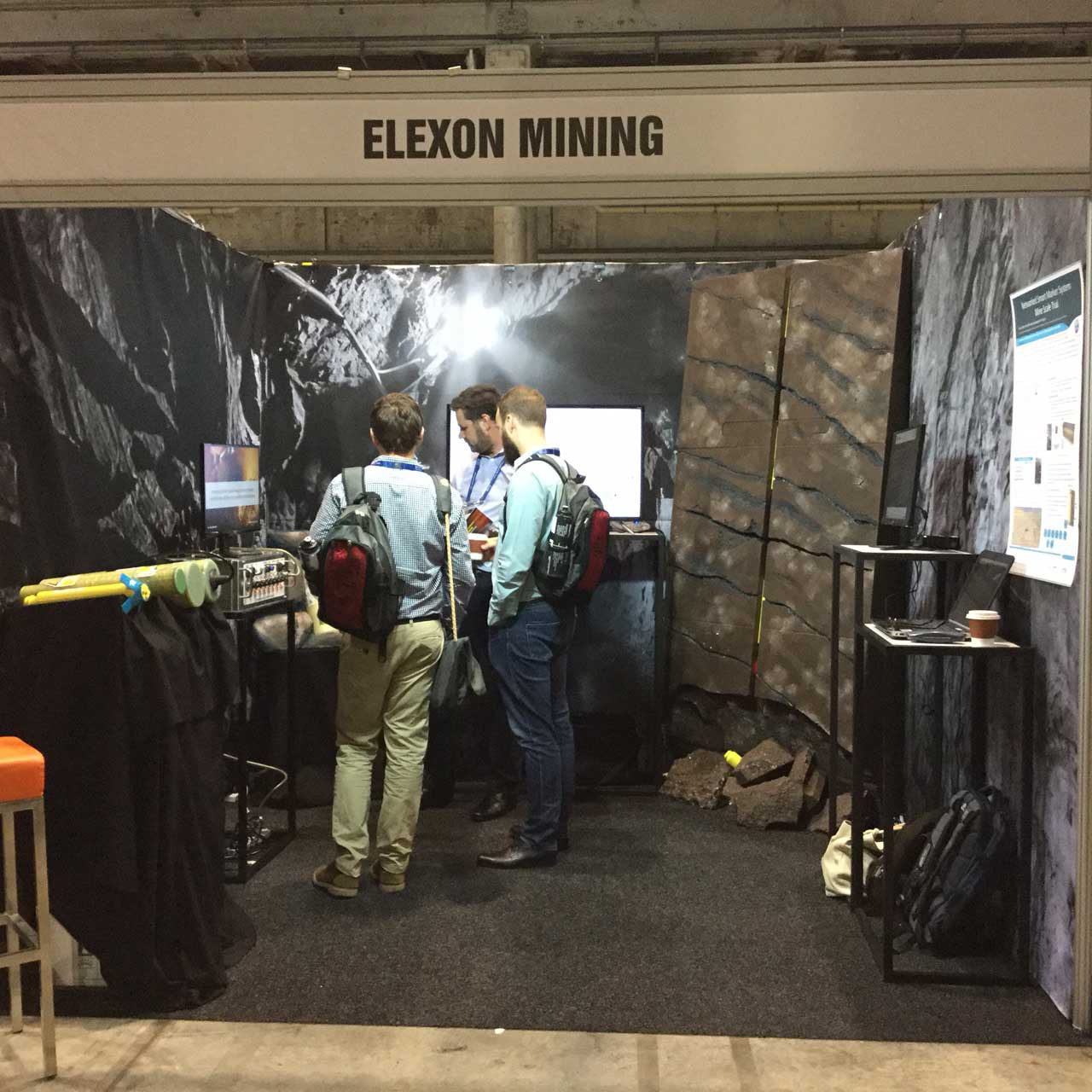

The introduction of Smart Markers has been a game changer to enabled mines to efficiently monitor ore recovery with minimal production impact and fast results.

The Reconciliation process and ore recovery monitoring are complementary methods focussed on optimising the sublevel caving system to the local geological and geotechnical conditions. Reconciliation indicates overall performance of the mining system. The understanding of ore recovery mechanisms identifies areas for improvement of ore recovery and reveals causes for under-performance in grade and tonnage. It also provides a guide to the maximum and minimum recovery estimation that any model should be bound by.

Together they enable mining to be engineered and optimised to maximise projects’ performance and economics. For example: Reconciliation may indicate that primary ore recovery is lower than predicted leading to potentially lower recovered grade and higher unit costs. It will not reveal the reason for the poor system performance. Drill and blast practices, suboptimal in the local conditions, are one likely cause for this shortcoming. Drill and blast may fail to mobilise ore in the targeted burdens and therefore achieve lower than estimated primary recovery. Drill and blast improvements, targeted with recovery monitoring systems, can increase primary recovery and therefore delay grade dilution. Potentially, this may reduce the need for low grade overdraw late in the mine life in attempts to recovery remnant resources believed to be remaining in the cave.

Small improvements in primary recovery over several recovery levels will have significant effects on project economics, reducing unit costs, improving margins and raising NPV.

Leave a Reply

Want to join the discussion?Feel free to contribute!